Release time:2023-11-27 15:08:36 Hits: Current position: Home > News

This article mainly introduces:

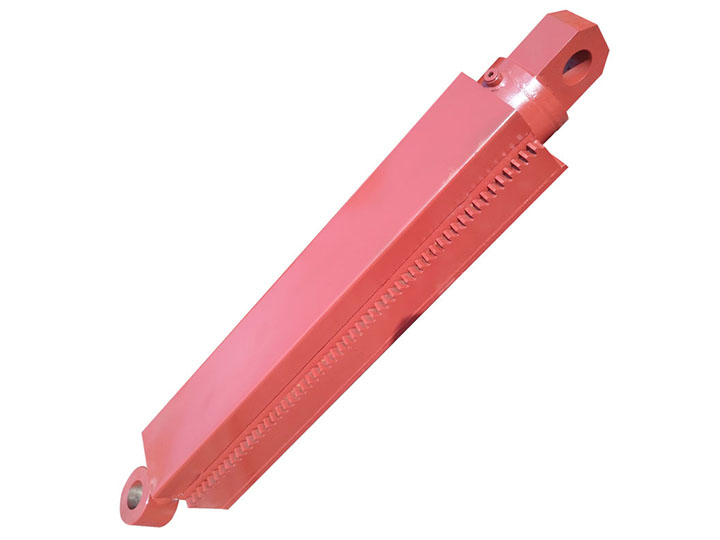

Belarus hydraulic cylinder,single rack cylinder manufacturer,single rack cylinder

(Belarus single rack cylinder,produced by Hengyu Hydraulic Co., Ltd)

single rack cylinder are widely used in Belarus,because of excellent fatigue and impact resistance,no need for deceleration device,long service life.So our company has designed single rack cylinder for customers from Belarus.

When purchasing the single rack cylinder, try to clarify the following parameters of the single rack cylinder: A. single rack cylinder diameter, rod diameter, stroke; B. Working pressure or single rack cylinder load; C. Working environment temperature; D. Working medium; E. Operating speed; F. Other parameters, such as connection form, mounting size, etc. In this way, the right single rack cylinder type can be found accurately and quickly.

single rack cylinder buffer valve inspection and maintenance: For the valve buffer single rack cylinder, the focus should be on checking the wear of the buffer valve spool and seat. Once it is found that the amount of wear increases and the seal fails, it should be replaced. It can also be repaired by using abrasive spool and seat matching grinding method.

The pressure of the sliding surface of the single rack cylinder piston is too large, resulting in sintering. The piston tilts due to the weight of the piston rod, resulting in the phenomenon of non-stiffness, or the pressure of the sliding surface of the piston rises due to the action of the transverse load, which will cause sintering. In the design of the single rack cylinder must study its working conditions, the length of the piston and bushing and the size of the clearance must be fully paid attention to.

The assembly work of the single rack cylinder has a great impact on the quality of the single rack cylinder: each part must be carefully cleaned before assembly; To correctly install the sealing device everywhere: when installing the sealing ring, pay attention to its installation direction to avoid oil leakage due to installation, and its lip should be equipped with a pressure oil chamber. In addition, because it is a YX-shaped sealing ring, it is necessary to pay attention to distinguish between shaft and hole use, do not install wrong; Because the sealing device is matched with the sliding surface, an appropriate amount of hydraulic oil should be applied during assembly; The special wrench should be used when the threaded coupling is tightened, and the torque should meet the standard requirements; After the piston and piston rod are assembled, it is necessary to measure whether the coaxiality and straightness on the full length are out of whack. After assembly, there should be no blocking sensation and uneven resistance when the piston assembly moves.

How to calculate cylinder speed?

If there is a throttle valve, the cylinder speed will be adjustable. When the throttle is fully opened, the speed of the cylinder reaches the maximum: maximum speed = oil pump displacement ÷ cylinder cavity cross-sectional area The displacement of the oil pump is a main indicator, which can be found on the nameplate, and some can also be known by the oil pump model; The cross-sectional area of the cylinder cavity can be easily calculated. Just make sure the units are the same. And because the cross-sectional area of the rod cavity and the rodless cavity of the cylinder is different, the speed of advance and retreat may also be different.

Why does the hydraulic cylinder ring?

1 Air intrusion into the hydraulic system is the main reason for noise 2 The relief valve is unstable, such as due to the improper combination of the slide valve and the valve hole or the contact of the cone valve and the seat is stuck by dirt, the damping hole is blocked, the spring is crooked or fails to make the spool stuck or move in the valve hole, causing system pressure fluctuation and noise. 3 Improper adjustment of the reversing valve causes the spool of the reversing valve to move too fast, resulting in reversing impact, resulting in noise and vibration. 4 Mechanical vibration, such as long tubing, elbow more and not fixed, when the oil flow through, especially when the flow rate is high, easy to cause pipe shaking; The rotating part of the motor and hydraulic pump is unbalanced, or the alignment is not good during installation, or the coupling is loose, etc., which can produce vibration and noise.